It first goes through a diagnostic (Step 1) of the overall performance, design and implementation of operational solutions structured around 5 key areas: voice of the customer, process efficiency, performance management, organization & skills, mindset & behavior.

A lean wave is a solution designed for companies or organisations that want to seriously improve the overall performance and maturity of their teams and departments towards operational excellence. It concretely challenges almost every aspect of the daily life of the business, from the service level we ambition to the work distribution routines, from the process sequences to the way we define and monitor our operational objectives.

The diagnose (3-4 weeks) is aimed at identifying & quantifying waste and inefficiencies in the daily operations and at prioritizing opportunities for improvement.

The design and action plan (2-3 weeks) operationalize insights from the diagnose and transform them into concrete improvement initiatives and realistic targets build around a coherent vision.

During the implementation (8-12 weeks), we support you in putting your new operating model into practice, and empower the management team and operators to progressively become owners of the change for long-term continuous improvement.

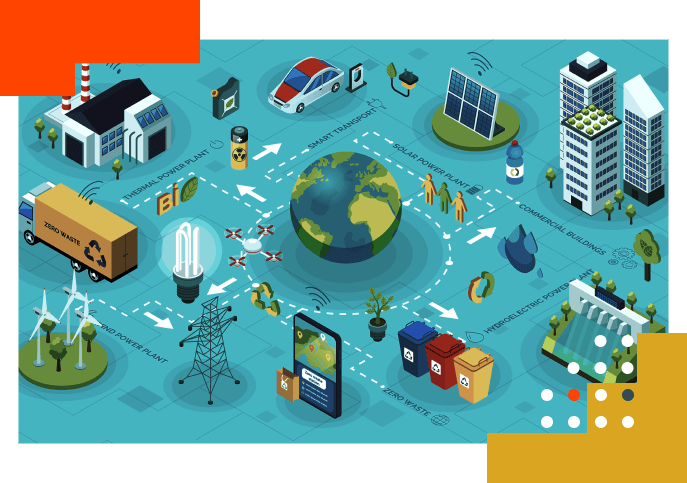

Let’s Make our Organisations More Lean and Sustainable