This article is part of the “How to be a green changemaker?” series on the Zerwaste blog. In this post, we will try to understand what Circular Economy is and what the associated opportunities are for companies.

Welcome back to the green changemaker Journey!

In February 2021, the European Parliament adopted a resolution on the new circular economy action plan demanding additional measures to achieve a carbon-neutral, environmentally sustainable, toxic-free, and fully circular economy by 2050, including tighter recycling rules and binding targets for materials, use, and consumption by 2030.

We have mentioned this CEAP in a previous article, but today, we would like to focus on what Circular Economy means for you and your business.

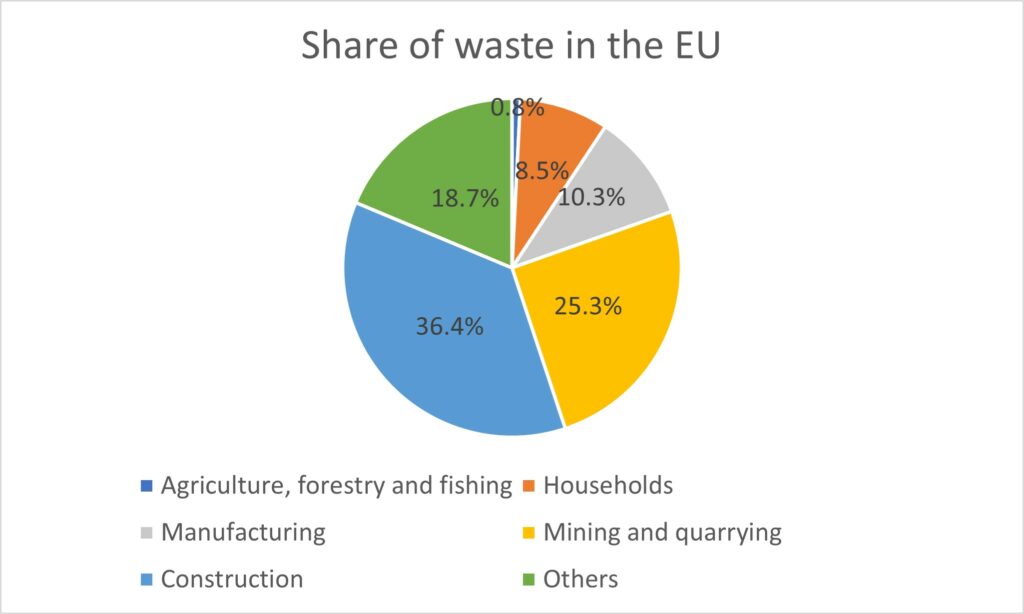

The Circular Economy (CE) is a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. In this way, the life cycle of products is extended. It implies reducing waste to a minimum. Nowadays, The European Union produces more than 2.5 billion tons of waste every year.

When a product reaches the end of its life (in CE), its materials are kept within the economy wherever possible. These can be productively used repeatedly, thereby creating further value. Products and materials contained are valued highly, unlike in the traditional, Linear Economic (LE), model, based on a ‘take-make-consume-throw away’ pattern.

Cradle to…

What does that mean?

“A circular economy is an economic system designed with the intention that maximum use is extracted from resources and minimum waste is generated for disposal” Pauline Deutz

Circular economy specialists regularly discuss 3 Cradle terms. What are we talking about? To clarify the subject here is an explanation of the three concepts

Cradle-to-gate

This term refers to the carbon impact of a product from the moment it is produced to the moment it enters the store. It takes the impact from the production of the material to the impact of shipping to the store.

For example, if we take an aluminum can of soda. The soda company can measure the impact of the materials needed to create their soda, including the drink itself and the choice of aluminum packaging, the impact of shipping necessary to deliver that soda can to a store near you. However, the soda company might assume that the consumer will drink the soda and have the option to recycle the remaining can, making it unnecessary for the company to measure the final destination of their product.

Cradle-to-grave

The term cradle to grave covers nearly the entire lifecycle of a product. This is an analysis from the raw materials to the disposal of the product to determine its full carbon footprint. Nevertheless, this method has some assumptions.

For example, the can of soda that is thrown in a landfill has a different footprint than one that is recycled. The company does not know what a consumer will do once their product is purchased. Nevertheless, the cradle-to-grave analysis strives to account for all the emissions of a product’s life cycle, with the end goal of reclaiming those emissions.

Cradle-to-cradle

This term can be defined as the design and production of products of all types in such a way that at the end of their life, they can be truly recycled, imitating nature’s cycle. It could be recycled or returned to the earth directly or indirectly.

Taking the example of the can of soda, once the can is thrown in the garbage, metal can be recycled. The company can use recycled metal to produce a new can.

One way to apply this philosophy is the Cradle-to-Cradle eco-design for products. It defines and develops cyclable products. Compared to conventional recycling, it maintains the quality of raw materials throughout the multiple life cycles of the product. It means that everything can be considered as a resource and that the notion of waste disappears: the right materials enter infinite cycles used in the right place at the right time. To simplify, a manufactured product must be able, once recycled, to produce the same product again, only the addition of renewable energy intervening in the cycle.

From 2005 to 2015, in the United States, Germany, and Holland, 150 manufacturers obtained C2C certification for about 2,000 manufactured products (jeans, office furniture, soaps, building materials…)

Conclusion

Measures such as waste prevention, eco-design, and re-use could save companies money while also reducing total annual greenhouse gas emissions. Currently, the production of materials we use every day accounts for 45% of the CO2 emissions.

Moving towards a more circular economy could deliver benefits such as reducing pressure on the environment, improving the security of the supply of raw materials, increasing competitiveness, stimulating innovation, boosting economic growth (an additional 0.5% of gross domestic product), creating jobs (700,000 jobs in the EU alone by 2030). Consumers will also be provided with more durable and innovative products that will increase their quality of life and save them money in the long term.