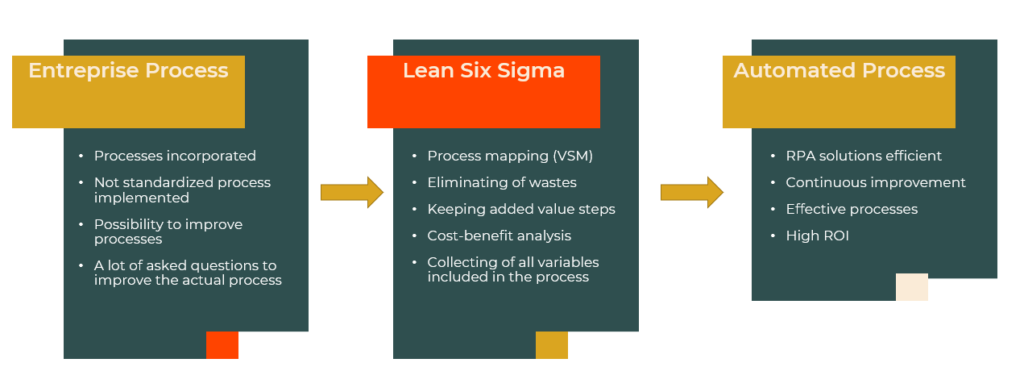

More and more scientific articles are dealing with the combination of two concepts: Lean Six Sigma (LSS) and Robotic Process Automation (RPA). RPA is a software technology that makes it easy to build, deploy, and manage robots that emulate human actions interacting with systems and software. It is a tool used to help operate more efficiently and is known for its potential to give employees more time to focus on creative, strategic work. This article aims to describe the benefits of using the LSS tool to help and identify what processes will be automated and how to prepare those processes before RPA projects.

One question to ask before deploying any RPA solutions: How can you improve an existing process? Lean Six Sigma can help you to answer this question. LSS is a process improvement methodology that focuses on identifying and eliminating waste from processes. It strives to make processes more effective and efficient by reducing variation and removing unneeded steps.

Automating a flawed process produces nothing more than waste and at a very fast rate. Therefore, before the development of a RPA project, it is critical to have a clear understanding of the process at hand as well as to conduct a comprehensive process mapping. This will offer you the best view regarding the different steps of the processes and allows you to take only added value tasks. The first step to prepare your processes for automation includes the examination of those processes for any of these eight types of waste known as Muda:

- Defects: failed processes or resulting rework;

- Over-production: production is more important than customers purchasing;

- Waiting: time spent waiting on someone or something else before you can move to the next process step;

- Non-utilized talent: when you don’t have the right people at the right positions;

- Transportation: time spent getting the product to the customer;

- Inventory Excess: products that are waiting before the sale;

- Motion Excess: a process which requires physical hand-off;

- Extra Processing: adding more value to a product than the customer requires.

It is possible to represent the process map via a VSM tool, for example, to sum up the processes and show only steps with an added value.

After elaborating the process and establishing the steps with and without value-added, you can proceed with a cost-benefit analysis. To do that, start by asking these questions:

- How much time does the process take?

- How many times per day/week/month is the process performed?

- What is the hourly rate of those employees using their time on these tasks?

The answers to these questions will give you the cost of operations. Furthermore, you will have knowledge of the cost and therefore the effort of automation will be worthwhile. Finally, make sure that all the requirements are included in the process (including steps, needs, assumptions, systems used …). After having collected all the variables included in the process, the team can develop the process automation.

The right preparation has to be made first to: “Do It Right The First Time”. Lean Six Sigma can be a real asset for gaining the insights you need. The LSS methodology could leverage RPA to free the existing workforce. When both concepts are used in tandem, it is strong leverage for continuous improvement. Indeed, LSS optimizes the process to achieve process excellence and make RPA solutions efficient.